Powering the Future: The Rise of Lithium-Ion Batteries for Cars

Lithium-ion batteries are driving the future of electric vehicles with high efficiency, long lifespan, and eco-friendly performance on the road.

Introduction: Electric Vehicles and the Rise of Battery Technology

In the past decade, electric vehicles (EVs) have evolved from niche products into mainstream transportation solutions. This rapid transformation is powered in large part by the development of lithium-ion car batteries. These advanced energy storage devices have become the gold standard for EVs due to their reliability, efficiency, and ability to support long-distance driving. As environmental regulations tighten and consumer demand for greener options grows, lithium-ion batteries are enabling carmakers to meet both performance expectations and sustainability goals.

What Exactly Is a Lithium-Ion Car Battery?

At its core, a lithium-ion car battery is a rechargeable battery that stores electrical energy by moving lithium ions between the anode and cathode through an electrolyte. Unlike older battery technologies such as lead-acid or nickel-metal hydride, lithium-ion cells can store much more energy in a smaller and lighter package. This makes them ideal for use in electric vehicles, where space and weight constraints are critical.

· Each lithium-ion battery pack consists of numerous individual cells arranged in modules. These are monitored by a sophisticated Battery Management System (BMS) to ensure safety and optimal performance.

Beyond the basic chemistry, modern lithium-ion batteries are engineered to handle high discharge rates needed for vehicle acceleration, rapid recharging at fast-charging stations, and harsh temperature environments. The inclusion of thermal management systems ensures stability during operation, reducing risks of overheating or fire.

Why Lithium-Ion Batteries Have Become Industry Standard

There are several compelling reasons why lithium-ion batteries dominate the EV market. Firstly, their high energy density allows vehicles to achieve impressive driving ranges on a single charge—often exceeding 300 miles in premium models. Secondly, they support rapid charging, meaning drivers can recharge 80% of their battery within 30–60 minutes, significantly improving convenience.

Additionally, lithium-ion batteries exhibit low self-discharge rates, allowing vehicles to retain charge over long periods of inactivity. Unlike earlier battery technologies, they are also free from “memory effects,” which can reduce capacity if the battery isn’t fully discharged before recharging.

Car manufacturers like Tesla, Mercedes-Benz, and BYD have all standardized lithium-ion battery systems across their EV lineups, citing both performance advantages and lifecycle economics. As mass production scales, costs have steadily decreased, making EVs more affordable for average consumers.

Beyond Cars: Diverse Applications of Lithium-Ion Batteries

While primarily associated with EVs, lithium-ion batteries have found roles across a wide spectrum of industries. Electric buses and delivery vans utilize high-capacity packs for urban mobility, while motorcycles, scooters, and e-bikes depend on compact variants for personal transport.

In logistics and warehousing, autonomous forklifts and mobile robots are powered by lithium-ion packs to reduce downtime and increase operational efficiency. Retired EV batteries are also being reused in grid-scale energy storage systems, helping to stabilize renewable energy sources like solar and wind.

This versatility demonstrates how lithium-ion battery systems have moved beyond automotive uses to become integral to the future of smart cities and energy resilience worldwide.

The Role of Battery Management Systems (BMS)

A lithium-ion battery’s efficiency, safety, and durability rely heavily on a robust Battery Management System. The BMS monitors key parameters such as voltage, current, temperature, and state of charge across all cells and modules. If any imbalance or fault is detected, the system can trigger cooling mechanisms, reduce output, or even shut down to prevent damage.

Furthermore, BMS units are now equipped with communication protocols that allow integration with vehicle telematics. This enables real-time diagnostics, remote monitoring, and predictive maintenance—features that are essential in both consumer vehicles and commercial EV fleets.

Environmental Considerations and Recycling Progress

While lithium-ion batteries eliminate tailpipe emissions, their environmental impact must be assessed holistically. Mining for lithium, cobalt, and nickel consumes energy and poses ecological challenges, particularly in developing regions. However, the industry is making strides in improving sustainability.

Recycling initiatives are now recovering up to 95% of materials from used batteries, reducing demand for virgin resources. Companies like Redwood Materials and CATL are developing closed-loop recycling systems, where battery components are refurbished and reintegrated into new cells.

Moreover, second-life applications allow EV batteries with reduced driving performance to serve in home energy storage or backup systems, extending their usefulness before final recycling.

Future Innovations in Lithium-Ion Battery Technology

The future of lithium-ion batteries promises even greater efficiency and safety. One major development is the solid-state battery, which replaces the liquid electrolyte with a solid ceramic or polymer. This reduces flammability, increases energy density, and could cut charging times in half.

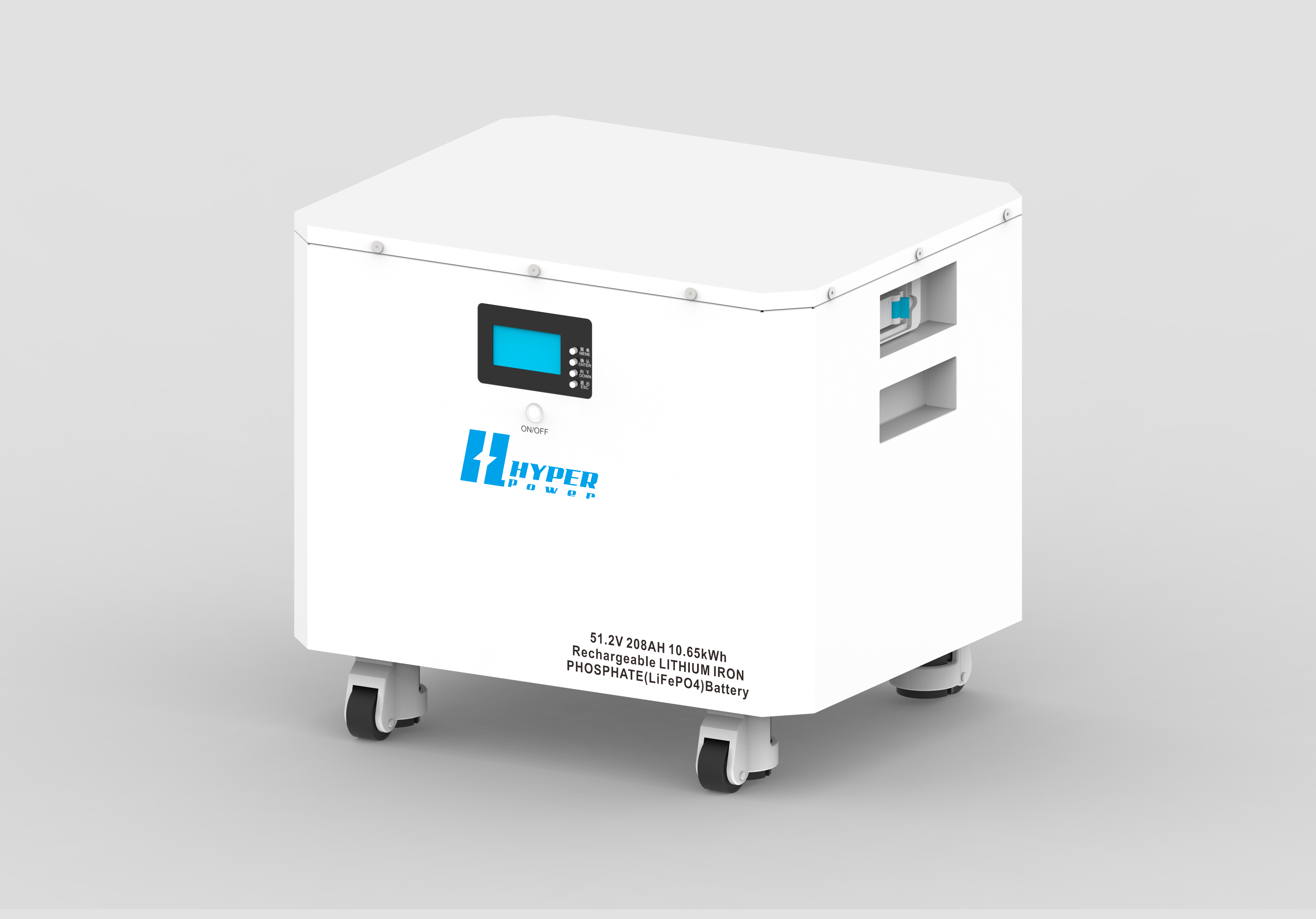

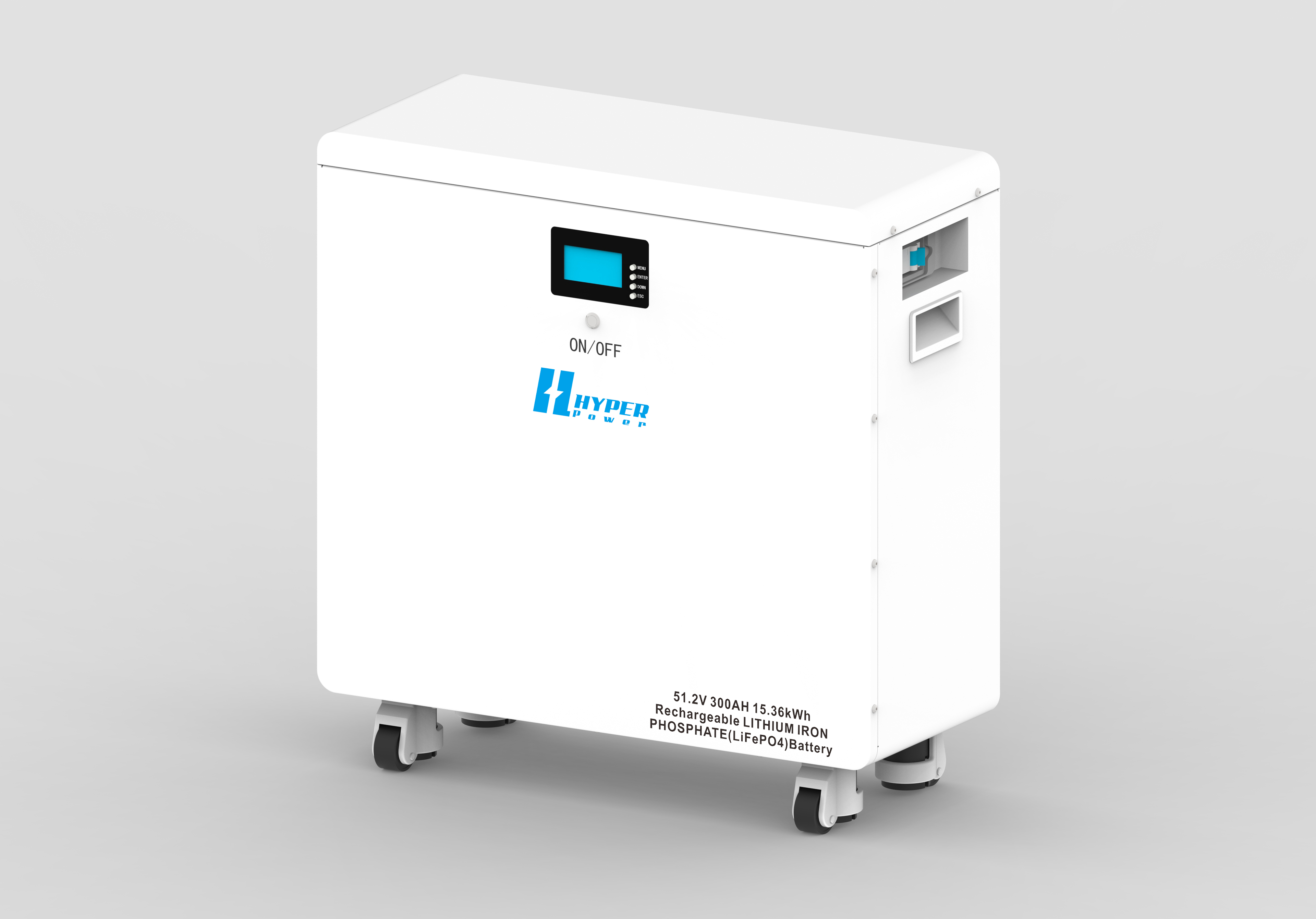

Researchers are also exploring silicon anodes as a replacement for graphite, offering up to 10 times more capacity. Meanwhile, manufacturers are experimenting with lithium iron phosphate (LFP) chemistries to create lower-cost batteries with excellent thermal stability for entry-level EVs.

These advancements are being fast-tracked by the increasing investment in battery R&D, both from governments and private sector players seeking to stay competitive in the electrification race.

Choosing the Right Lithium-Ion Battery for Your Vehicle

If you’re in the market for a lithium-ion battery—whether as an EV owner, fleet operator, or aftermarket supplier—there are several criteria to evaluate:

· Energy capacity (measured in kWh), lifecycle (number of charge/discharge cycles), safety certifications, manufacturer reputation, and warranty terms.

A reputable battery supplier will also provide technical documentation, installation support, and aftersales service. For fleets, choosing batteries with cloud-based monitoring and performance analytics is increasingly becoming a best practice.

FAQ: Lithium-Ion Batteries for Cars

Q1: How long do lithium-ion car batteries typically last?

A1: Most EV batteries are designed to last between 8–15 years or 150,000–300,000 kilometers depending on usage, temperature, and maintenance.

Q2: Are lithium-ion batteries fire-prone?

A2: While incidents are rare, high temperatures or manufacturing defects can pose fire risks. That’s why BMS, thermal protection, and certified designs are essential.

Q3: Can old lithium-ion car batteries be recycled?

A3: Yes. A growing number of recycling facilities can extract valuable metals like lithium, cobalt, and nickel for reuse in new batteries.

Q4: Do all electric vehicles use the same type of lithium-ion battery?

A4: Not exactly. While they are all lithium-ion based, chemistries (like NMC, LFP, or NCA) vary depending on the vehicle’s range, cost, and performance goals.

Blog

Maximizing Energy Independence with Home Lithium Battery Storage

How Residential Photovoltaic Energy Storage Systems Empower Sustainable Homes

Why the 12V Lithium Ion Car Battery is the Smarter Automotive Power Solution — Insights from JEJE Energy

-Charging.png)

.jpg)